Future Proofing for Sustainable Design

No matter the budget, every project can implement practical design strategies to improve energy efficiency, reduce water consumption, and create healthier and more productive indoor environments. That said, first costs can often limit owners’ ability to implement solutions like solar photovoltaic (PV) systems or rainwater capture and treatment systems. While there are a variety of local, state, and federal programs and incentives that should be explored, some projects simply do not have the construction budget to include certain strategies at the onset.

Rather than abandoning these strategies all together, design teams should encourage owners to take a phased approach and ensure critical infrastructure and capacity is incorporated into the project to allow for easier and cheaper future implementation. One example of this approach can be highlighted with solar photovoltaic systems.

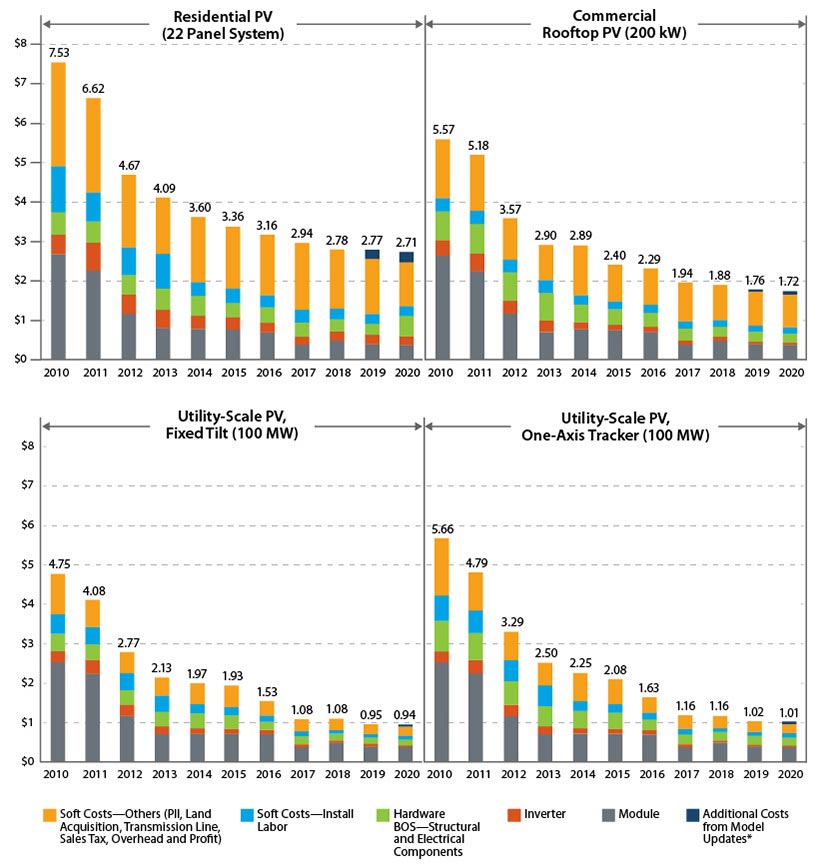

The National Renewable Energy Laboratory’s (NREL) has tracked and modeled solar photovoltaic system costs since 2009. Each year the NREL has released a report benchmarking the costs for residential, commercial, and utility-scale systems. The NREL analyzes the capital costs (using bottom-up accounting for all system and project development costs) and the levelized cost of energy for such systems.

The graph below highlights the decade-long trend of declining costs for rooftop PV systems. As technology improves, new incentives are offered, energy costs rise, and pricing drops, the return on investment (ROI) for a PV array continues to become more favorable.

https://www.nrel.gov/solar/market-research-analysis/solar-installed-system-cost.html

If first cost constraints don’t allow for a PV system, but an owner wants to maintain flexibility to install one in the future, the following should be considered when designing a new facility:

- Conduct basic energy modeling to understand facility loads and set goals around PV production to right size the PV system.

- Conduct a solar site survey to understand sun potential of the site.

- Evaluate building orientation and roof design to optimize sun exposure.

- Ensure the structural design of the building and roof account for future loads for a PV array so there is adequate capacity to handle the additional loads of the system.

- Based on the size of the expected PV array ensure that the electrical room is adequately sized to accommodate a future transformer and other gear.

- Ensure there is adequate space next to the main electrical panel to allow for dedicated future PV service panel.

- Consider running additional electrical conduit (EMT) from electrical panel to roof.

- Consider the need for battery storage and identify space to accommodate.